One of the challenges of ship design is the propulsion system. The traditional propeller and drive shaft present problems such as:

- Complicated gearing systems which are an operating and maintenance challenge

- Long drive shafts which take up precious space in the ship

- Multiple points of watertight seals that have proven to be less than watertight in damage situations

- Shaft bearings that are prone to overheating and require lubrication and cooling

- Complex lubrication systems for shafts and gears with sea water influx being a common problem

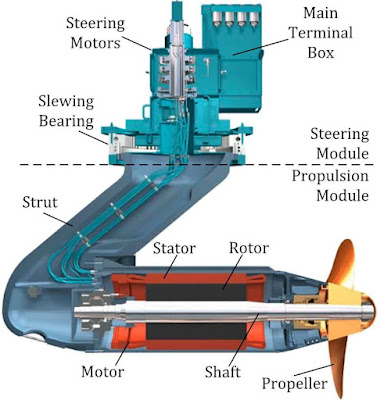

One potential solution is the pod system in which an electric drive motor and propeller are mounted in a pod external to the ship’s hull. This eliminates the shaft, many bulkhead penetrations and seal points, complicated gearing, etc. The pod rotates via a small steering motor mounted in the ship’s hull directly above the pod’s mounting flange. The only penetration of the hull is the electric cables from the power generating unit to the electric motor in the pod. Large commercial pods may have maintenance access hatches built into the pod mount.

|

| Typical Propulsion Pod Concept |

Pods can be either push (traditional rear mounted propeller) or pull (front mounted, like an airplane) and can be either fixed or rotating (azimuthing). Some ships have used a combination of fixed and rotating pods. Front mounted (pull) pod props have been claimed to reduce cavitation compared to conventional push propulsion systems due to operating in less disturbed water flow.[2]

|

The features of pod systems include:

- No gear systems required

- Space saving

- Pods can rotate 360 deg

- 2-25 MW per pod

- Eliminates need for a rudder

Pods have a range of power outputs from 2-25 MW per pod. As a point of comparison, the Burke’s propulsion system consists of 4x LM2500 turbines connected via gearing to two propeller shafts producing a total of 78 MW of power. Two large pods would produce 25 MW and three would produce 75 MW which equals the conventional Burke output.

|

| Various Types of Pods |

Pods have been extensively fitted to icebreaking vessels and cruise ships, among others. Some examples include:

Rolls Royce Mermaid Pod

The QUEEN MARY 2 has four Rolls Royce Mermaid podded propulsion systems, the first four-podded installation to date and the largest output for any podded-driven vessel. The system comprises two fixed and two azimuthing pod units delivering a combined output of more than 85 MW, which gives the ship a service speed of 30 kts. [1]

ABB azipods are produced in a range of sizes and power outputs. For example,

The luxury polar expedition cruise ship, due delivery for the French cruise company Ponant in 2021, will feature two Azipod VI propulsion units, designed for the most challenging ice conditions.

Upon delivery from Norway’s Vard Søviknes, a Fincantieri Company, the cruise ship will take passengers to unexplored destinations in Arctic and Antarctic waters. In the harsh conditions of ice-covered seas, Azipod units with six-meter propellers and combined power of 34 MW will help the vessel achieve greater maneuverability and efficiency, as well as lower the environmental impact. Due to minimal noise and vibration, Azipod propulsion will also improve passenger and crew comfort. [3]

On a larger scale, the Royal Caribbean cruise ship, Oasis of the Seas, uses 3x ABB 20 MW (60 MW total) rotating azipods.

Some naval examples of pod propulsion include:

- French Mistral LHD class uses 2x 7 MW pods. The ship is 650 ft long, 20,000 tons displacement, and can achieve 18 kts.

- Australian Canberra LHD class uses 2x Siemens Navantia 11 MW pods. The ship is 757 ft long, 27,500 tons displacement, and is rated at 20+ kts.

Summary

Pods seem like a worthwhile possibility for naval vessels. The reduction in complexity, equipment, and bulkhead/hull penetrations make pods an attractive alternative to convention systems. In particular, eliminating the complex combination gearing systems that the Navy seems completely unable to operate and maintain would significantly reduce the number of ship breakdowns the Navy has encountered of late. How pod systems would fare in combat and damage control situations is, of course, unknown and would have to be tested.

At the moment, I see a lot of upsides and no real downsides to this technology.

________________________________

[1]https://www.wartsila.com/encyclopedia/term/mermaid-propulsion-unit

[3]https://www.maritime-executive.com/article/one-hundred-cruise-ships-feature-abb-azipod

Still need the skeg of course.

ReplyDeleteI can see where it would help with damage control. The pods give built in redundancy for your mobility. Add in multiple generators for redundancy on the power generation side should help too.

ReplyDeleteAlthough I would suggest doing shock tests on the pods on the pods before designing a ship with them. Just attach them to the underside of a barge and start with the explosives. Probably will find that you want to armor them up a bit compared to commercial sets. But you don't know till you try.

I wonder what the acoustic signature would be with these in comparison to a traditional system?

ReplyDeleteLutefisk

No data so pure speculation on my part but with no combining gear, shaft, lube system, etc. inside the hull, there would be less internal noise.

DeleteExternally, I've read statements that the pull-type pods have less cavitation, hence less noise, due to less disturbed water flow impinging the props.

On the other hand, the pod motor is external and would be a noise source although, presumably, it would be acoustically isolated.

So, my uninformed guess would be that it would be quieter, overall.

Seems like if you locate pods both fore and aft, you build in excellent redundancy of power is being generated also in two different locations.

ReplyDeleteThese are very common on large cruise ships. You don't need harbor tugs saving lots of money. Great maneuverability at slow speed as they can spin the ship to dodge missiles and torpedoes. Time in yards is greatly reduced as pods can be swapped out.

ReplyDeleteI was on an 80,000T cruise ship with azipods and a bow thruster. Went to the berth without tugs. Just pulled up alongside and walked straight in on the pods and thruster.

DeleteWe had to MEDEVAC a crew member after we left Barbados. Turned around and went back. Pulled in alongside the berth, used the thruster and azipods to walk straight in, then held the ship there without putting lines over. Put the brow over, evacuated the guy to an ambulance, walked back out into the bay, and were off. No lines put over, so much faster than a normal mooring.

DeleteThe Perrys had two pods good for 6kt.

ReplyDeleteAnyone know is they were used in ASW exercises ?

IIRC, those were for emergency "get home" use only.

DeleteHonest question: Are China/Japan/etc. using pods for their warships?

ReplyDeleteMaybe not a "pure" warship, but China has them for civil "military-capable" ships like below

Delete"Zhenhua-33 is the biggest civil ship in China to date that can be used for military purposes."

https://www.globalsecurity.org/military/world/china/mlp-zhen-hua-33.htm

from above:

"Kongsberg DP-II system is fully integrated with two tunnel thrusters at the bow and three fully-revolving main azimuth thrusters at the stern."

China also have (will have?) an icebreaker that uses it as below link shows:

https://www.marinelink.com/news/chinesebuilt-icebreaker409553

And "Shenhai 01" the rescue vessel below

https://www.marineinsight.com/shipping-news/chinas-first-hybrid-electric-rescue-vessel-features-full-scope-of-abbs-electric-and-digital-solutions/

For Japan, again, no warships (that I know of, feel free to correct me if I am wrong) but from 2004 "the ferries AKASHIA and HAMANASU built by Nagasaki Shipyard (MHI) are the first vessels provided with the CRP-Azipod propulsion"

https://www.wartsila.com/encyclopedia/term/crp-azipod-propulsion-of-the-ferries-akashia-and-hamanasu

For etc. well, here are the real warships: the Mistral class from France(which if you followed the news had once been earmarked to be sold to Russia, but due to their actions in Ukraine, was stopped, and later sold to Egypt), the Dutch Rotterdam class, the Spanish Galicia class, and the Canadian Kingston class, and of course whatever I missed.

By the way I want to thank ComNavOps for the "Armor Compendium" because it is always nice to have everything like all links etc.in one place I can bookmark once to easily access all I want quickly, thank you!

Too bad that we don't build merchant ships where we could try out this technology.

DeleteLutefisk

Oh and for "real" fighting ships (or at least more "fight-capable") and to add to "etc." there is the Russian "Ivan Papanin-class multi-purpose reefer" transport that uses the Azipod electric propulsion system

Deletehttps://tass.com/defense/1350061

From above:

"The Ivan Papanin-class Arctic reefer vessel can carry a mobile Kalibr-K missile system. This will require three standard cargo containers that can be delivered to the ship and unloaded ashore by 40-tonne shipboard cranes"

And also:

"Given the need to unload the mobile missile system onto the shore, the fourth container can be installed aboard the reefer ship to accommodate the Kalibr-K combat squad, the project supervisor specified"

n of one here, but I have pods on my pleasure boat...bees' knees. Maneuverable, easy maintenance, built to separate in an emergency, more efficient than a shaft due to straight-line forward translation of thrust, less likely to hull breech if hit by the bottom.Sure, my favorable experience is anecdotal, ...but I bet Naval purchasers have spent billions on less reliable sources than that. : )

ReplyDeleteThe FR Mistral class and the SP/AU Juan Carlos/Canberra class are very interesting to me.

ReplyDeleteAs Jjabatie wrote in the AAV thread,

"The Navy lost sight of what the Marines did, and what they needed. Abandoning NGFS, simpler troop ships and landing craft got us here. Multi-purpose, high-end ships too valuable to risk inshore got us here. The Marines trying to be an air force, and the Navy allowing it got us here. And giving away their armor was probably the last nail in the coffin."

The $3.8B LHAs/LHDs and $2.2B San Antonios are too big and valuable to risk close inshore. From out where they operate, they cannot get tanks and artillery ashore because of a lack of viable ship-shore connectors—boats are too slow, helos and V-22s can’t lift the load, and LCACs have been ruled out as unreliable. They have effectively neutered the Marines into a light artillery force that is little more than boy scouts with BB guns.

I would like to see the Gator Navy go back to simpler troop (and equipment) ships. The Juan Carlos/Canberra and Mistral classes could be the high end, replacing the current amphibs with ships costing half to a third as much, complemented by a simpler LPD/LSD like the UK Albion, a conventional LST, a LPA/LKA that could be a converted merchant, supported by an NGFS package including battleships with 16-inch guns and missiles, cruisers with 8-inch guns and missiles, and an inshore fire support frigate with 5-inch or 155mm guns and a bunch of rockets like a bigger version of the old LSMRs. Excluding the cruisers and battleships, an entire amphibious squadron could be built for about the cost of one LHA/LHD.

That leaves the question of what to do with the LHAs/LHDs and San Antonios. HII has proposed an ABM/BMD ship on the San Antonio hull, and that would appear to be a need, so convert them and deploy them around Guam, Yokosuka, Sasebo, Pearl, Rota, Naples, and major USA cities. If we just parked the LHAs/LHDs, Congress would have a cow over idling useless $4B assets. The best use would seem to be interim Lightning Carriers, until we could get a new class of conventional carriers designed and built, to increase carrier numbers and complement new nukes that would be cheaper and more reliable than the Fords. Replace the troop and equipment spaces with larger hangars and aircraft maintenance spaces so you could handle probably 40 aircraft, and add ski jumps so you could launch with more fuel and ordnance.

I know ComNavOps doesn’t like the Lightning Carrier concept. I know it is nowhere near the equal of a CVN supercarrier, and I don’t really want to rehash that debate. But as long as the USN has the only supercarriers, they’re not going to go up against supercarriers. Worst case, a force of 10-12 Lightning Carriers and no supercarriers would still give the USN the strongest naval air force in the world. And we are still going to have supercarriers. This is just a cheap way to supplement them until we can get something like modernized Kitty Hawks into the fleet. It’s almost like finding free money.

For a lot less than the USN is looking to spend, we could have an amphib force that could actually do assaults, return the Marines to their amphibious/expeditionary roots, provide ABM/BMD protection for advance bases and major cities, and supplement our naval air on an interim basis until we could get a better solution in place.

So why not take one of thise wasted DDG-1000 testbed vechicles and put pods on it. Lord knows it has the electrical power and with faulty oil coolers you could boost reliability tremendously. Testing on a parge naval vessel would actually give some value from that program. Even if the hull is not optimized for pods.

ReplyDeleteThe Burke Class has reversible, controllable-pitch propellers that enable her to stop in a short distance in an emergency. With propulsion pods, without the propeller pitching mechanism, you would have to slew the pods 180 degrees to slow the ship down, which by itself would take some time, especially at higher speeds. The basic issue how well can a Burke-like ship perform an emergency stop with propulsion pods?

ReplyDeletethey are elecctric motors. Can't they just stopm and reverse direction? There is no shaft.

DeleteIn that case, you would have to spin your propellers down and then spin them back up in the opposite direction. I'm not sure which would be faster.

DeleteAt the same time, wouldn't propulsion pods make your primary means of movement more susceptible to damage from torpedoes and mines? At least with conventional propulsion systems, the engines are protected within the hull.

Another consideration is that variable-pitch propellers can be adjusted to minimize cavitation.

"wouldn't propulsion pods make your primary means of movement more susceptible to damage from torpedoes and mines? At least with conventional propulsion systems, the engines are protected within the hull."

DeleteIf you encounter damage (explosion) severe enough to render the pod inoperative, that same amount of damage would likely have rendered conventional props, shafts, and rudders inoperable, too.

"variable-pitch propellers"

I don't know any engineering reason why pod props couldn't be made variable pitch. I suspect they're not just because no one has had a reason to want them to be, yet.

"If you encounter damage (explosion) severe enough to render the pod inoperative, that same amount of damage would likely have rendered conventional props, shafts, and rudders inoperable, too."

DeleteAgreed. But, I'd suspect repairing a damaged propeller, shaft, or a rudder would be much easier to repair than a damaged propulsion pod.

Everything that moves your ship is located within that pod. Any sea water exposure to the electrical motor is going to ruin the electrical motor. Though the electrical motor could probably be sealed to provide additional protection. Maybe the propulsion pods can be designed with replaceable sections, though maneuvering heavy pieces of equipment under water would be as a challenge as well.

"I don't know any engineering reason why pod props couldn't be made variable pitch."

When you can slew your propellers 360 degrees, you don't need variable pitch propellers. But, adding that capability would certainly add additional complexity and weight to your design. Which would make your pods larger and maybe slower to slew. Though that could be offset by a larger, more powerful Steering Module.

"But, I'd suspect repairing a damaged propeller, shaft, or a rudder would be much easier to repair than a damaged propulsion pod."

DeleteThen you'd suspect incorrectly. A pod is a module. You simply replace the entire pod. While rudders and props can also be replace, shafts cannot, at least not without truly major efforts. Also, it would be much easier to replace a single pod than a rudder, prop, and shaft.

"Then you'd suspect incorrectly. A pod is a module. You simply replace the entire pod."

DeleteWhat do you suppose a Burke-size propulsion pod would weigh? Five tons? Ten tons? Twenty tons? More?

How big are it's propellers? Maybe ten to twelve feet in diameter.

I'm not sure how one replaces a bulky and heavy propulsion pod in the middle of the ocean. It's certainly not something you would carry in stores.

"Then you'd suspect incorrectly. A pod is a module. You simply replace the entire pod."

DeleteHow big and bulky would a Burke-size propulsion pod be?

Something like that would easily weight many, many tons with propellers in the 10 foot diameter range.

I just don't see how one maneuvers something that big and bulky under the water in the middle of the ocean.

It's funny how you're moderating responses. You're usually spot on in your assessments, but this one isn't ready for prime time and probably never will be.

Delete"I'm not sure how one replaces a bulky and heavy propulsion pod in the middle of the ocean."

DeleteYou don't replace it in the middle of the ocean any more than you could a rudder, prop, or shaft. You need a drydock as you would for any of those items.

Where did you get the idea that you could replace such a thing in the middle of the ocean?

"It's funny how you're moderating responses. You're usually spot on in your assessments, but this one isn't ready for prime time and probably never will be. "

Delete????? I only moderate comments older than 7 days and that's only to reduce spam. I have no idea what you're trying to say. I suspect you don't really mean 'moderate' but I have no idea what you do mean. Try again?

Are you talking about the delay in comments appearing that fall into the 7+ day moderation folder? If so, yes, there is an unavoidable delay in publishing them until I get a chance to okay them as 'not spam'. I try to check the moderation/spam folder several times a day but there will be an unavoidable delay. Be patient and trust that a comment will appear. For example, it looks like you repeated this comment of yours multiple times, perhaps because you didn't see it appear immediately? If so, again, trust that it will appear as soon as I've had a chance to verify it as 'not spam'.

If you're talking about something else, then I'm lost. Try again.